How Much Are Hydraulic Reclosers Costing You?

Back to Top

Single-phase reclosers are workhorses for your overhead distribution laterals. They reduce sustained outages, improve reliability, and help your metrics look better to regulators and customers alike.

With benefits like that, it’s no longer a question of if you need single-phase reclosers on your laterals—but which one.

If you’re looking to make the change to another type of recloser, consider the long-term differences between hydraulic and electronic.

The Cost of Continued Oil-Based Operations

Every utility weighs upgrade costs carefully. Electronic reclosers like the TripSaver® II Cutout-Mounted Recloser cost more upfront than oil-based hydraulic units. But when you look at what's required to keep each type of device running over time, you start to see a different story.

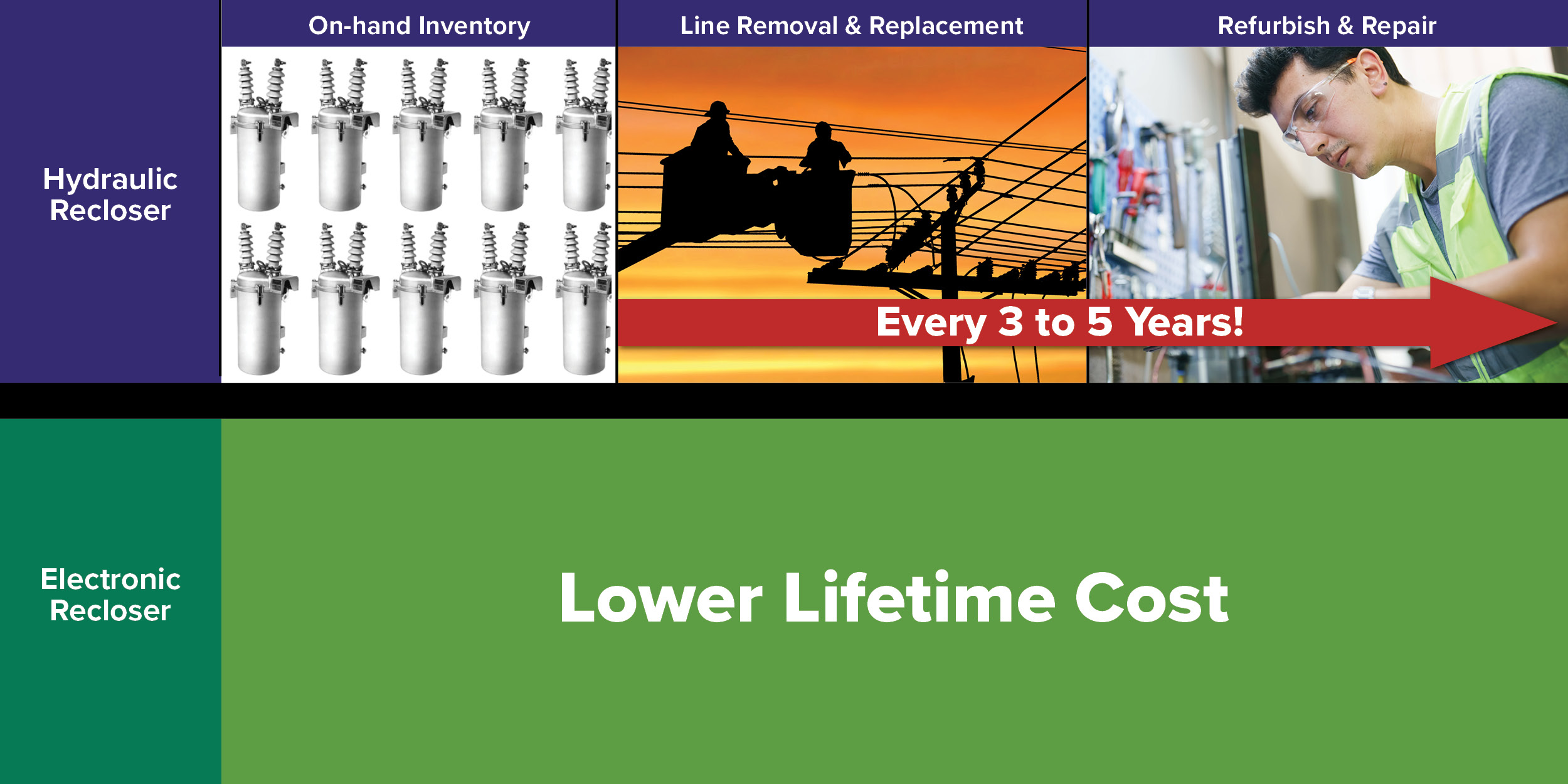

With hydraulic reclosers, oil checks are needed every 3 to 5 years to maintain performance. Tank degradation, worn out parts, and failing components also demand attention. On-hand inventory is a must to have temporary replacement units installed in place of units undergoing repairs.

In addition to labor costs for line removal and replacement, the repair and refurbishment procedures can run anywhere from $600 to $1,000. That’s if it’s possible. In some cases, obsolete parts may be irreplaceable, and you’re now looking at the cost for a fully refurbished unit or full replacement.

Considering that electronic reclosers eliminate virtually all these ongoing expenses, hydraulic recloser repair starts to look economically inefficient.

The Reliability Risk with Delaying Maintenance

Defer maintenance on your hydraulic reclosers, and your reliability suffers. Oil degradation and sludge buildup can alter the flow of the hydraulic fluid, slowing down the trip function and altering the recloser’s protection response without warning. The device may not respond when expected or over-trip, causing unnecessary outages. And with rising reliability and insurance mandates, running units without proper upkeep isn’t viable.

Weighing Your Replacement Options

High maintenance costs make replacement the more practical path forward. A refurbished hydraulic recloser may cost less initially, but recurring maintenance and future repairs remain part of the equation.

Today’s vacuum-bottle-based hydraulic reclosers reflect a shift in the market. Their asset cost is high—not just compared to oil-interrupting models. With fewer low-cost options remaining in the hydraulic category, the case for switching to electronic becomes even stronger.

But it’s not just about upfront cost. Even hydraulic reclosers with vacuum technology come with limitations:

- Maintenance is still required, though less frequent and costly than oil-based units.

- On-hand inventory is a must, as you need to have additional units available to stand in for those you’re servicing.

- Reliability risks persist, due to a complex system of components vulnerable to leakage, wear, and failure that can compromise the interrupter’s performance.

- Protection flexibility is limited because built-in protection parameters require hardware changes for updates, lead to excess inventory, and cap trip ratings at twice their continuous load.

What This Means for Your Budget

Avoided truck rolls for outages and limited maintenance help electronic reclosers reach break-even quickly. After that, the savings compound year after year—while hydraulic units continue to generate operational expenses through ongoing repairs and replacements.

Electronic Reclosers Offer Even More Benefits

The cost savings are compelling, but an electronic recloser like the TripSaver II recloser delivers additional value that's harder to put a price tag on.

| Capability | Electronic Advantage | Why It Matters |

|---|---|---|

| Environmental Impact | No oil | No disposal costs or leakage |

| Installation | Cutout-mounted designs available | Familiar to crews – installs like a fuse |

| System Coordination | Time-current curve variety | Easy integration and device coordination |

| Future Scalability | User-programmable settings and communications flexibility | Can adapt as your system grows without hardware changes |

| Operational Intelligence | Event data | Offers visibility into fault response to optimize performance |

The Long-Term Value Play

Step back and look at the full picture, and the upfront price difference between hydraulic and electronic reclosers fades fast. What remains is better system performance coupled with operational efficiencies and savings.

The result? More budget for system improvements and other priorities.

Ready to Switch?

The costs speak for themselves, but sometimes the best way to see the difference is hands-on experience. Consider replacing hydraulic reclosers with electronic reclosers the next time you perform maintenance. You can emulate the existing protection curves to easily slot them into your system. You’ll be able to lock in accurate performance without the added upkeep.

The real question isn’t whether electronic reclosers like TripSaver II reclosers are worth the investment. It’s whether you can afford to keep absorbing the hidden costs of hydraulic recloser technology. So—what’s your next step toward smarter, more efficient lateral protection?

Try the alternative—request a TripSaver II demo

Contact us to explore how easily the TripSaver II Cutout-Mounted Recloser can integrate into your system to enhance reliability and savings.